Augmented Reality Improves Industrial Safety

iManufacturing plants are filled with moving parts. The amalgamation of fast-moving machinery, equipment, and vehicles mean that these plants can be dangerous places. Although most manufacturing plants have stringent safety regulations, mistakes still happen. With progressively complex production technologies, industrial safety continues to be a concern for many companies.

Augmented reality (AR) offers a way for employees to interact with technology and machines in ways that are not only more efficient and effective, but also safer.

Industrial safety in manufacturing is critical

The International Labour Organization reports that over 313 million on-the-job accidents occur a year, which costs the global economy approximately $3 trillion dollars a year. Work-related injuries can create multiple negative repercussions throughout an organization, starting with the employee. From a business point of view, it can halt production, suspend cycle times, and prevent manufacturers from meeting production deadline demands. On top of the human cost, injuries at work can be incredibly costly. Lawsuits and health insurance can negatively impact the bottom line. Running a safe work environment is the responsibility of an organization and every employee and developing ways to enable a safer workplace, like augmented reality, are being embraced.

Augmented reality to improves worker safety

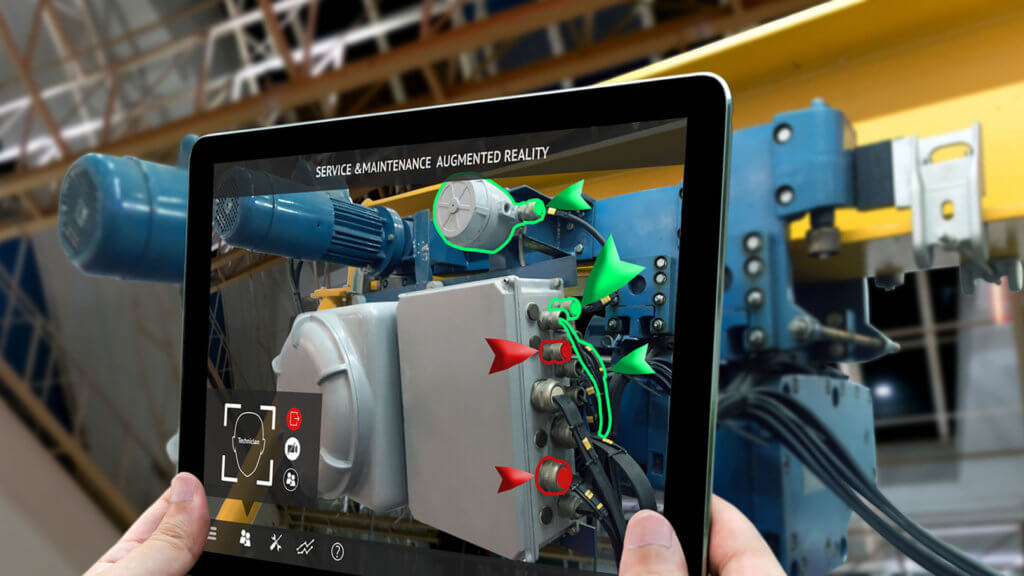

Augmented reality is the blending of the digital and physical world — it overlays information onto your field of view. AR can be used to provide industrial safety through broad scope training, thorough orienting procedures, real-time instruction from experts, and instant hazard warnings to employees on the ground.

Improve the quality of training and on-boarding

AR has been shown to be enormously effective in improving the learning curve for new hires in manufacturing plants. This makes the employees less likely to make possibly hazardous mistakes. In fact, industries who are using PTC’s augmented reality training for new employees have indicated a decrease of 30 to 50 percent in training time for new employees.

AR also helps improve training quality. Studies have shown that training through augmented reality helps workers to recollect more knowledge. With AR’s noticeably improved training, employees are less likely to make critical errors on the floor.

3D work instructions

Outdated operation manuals are hard to interpret and learn from. Operators, assemblers, and technicians need to be aware of specific safety risks when working on various types of equipment. 3D work guides can help employees prevent a malfunction from occurring in the first place by giving them a greater understanding of the parts they are working on. Through AR, you can place 3D work instructions over a worker’s field of vision. This gives a more immersive picture of a part and makes it easier for an employee to visualize the task at hand.

Real-time safety alerts

AR can be used to warn an employee to possible dangers. In the past, a worker would have to rely on their own knowledge when a safety level had been exceeded, leading to potential human error. AR headsets can be connected to the broad network of information provided by machines. Thi information can be passed through the augmented reality headsets to initiate real-time alerts when a procedural step could be dangerous. These real-time warnings have the possibility to dramatically change manufacturing workplace safety.

Accessibility to remote experts improves industrial safety

With 22 to 25 percent of the manufacturing workforce encroaching on retirement, the skills gap is broadening. This loss of experience poses a unique safety risk to the manufacturers. In the same way that employees need to have hands-on training and safety warnings, they also need to be able to talk to experts when performing unfamiliar or complex tasks. Technologies like Vuforia Chalk allow workers to directly contact experienced, senior workers when they are about to undertake a potentially hazardous process. Having a remote expert on hand is the support that workers need in today’s ever-evolving manufacturing world.

At Transform Interactive we provide platforms that can provide substantial impact on increasing workplace safety, and allow businesses to more effectively on-board and train their workers. If you’re looking to leverage current technology to solve these issues, please contact us!